Snow Replica

The method for preparing the replica of snow crystal (snow replica) was first reported by V. J. Schaefer in the United States in 1941 1). In this method, a solution of plastic dissolved in an organic solvent (replica liquid) is prepared. The snow crystal is then placed on a glass slide coated with the replica liquid, and the solvent is air-dried at a temperature below 0°C to form a thin film of plastic, preserving the outline of the snow crystal with the plastic.

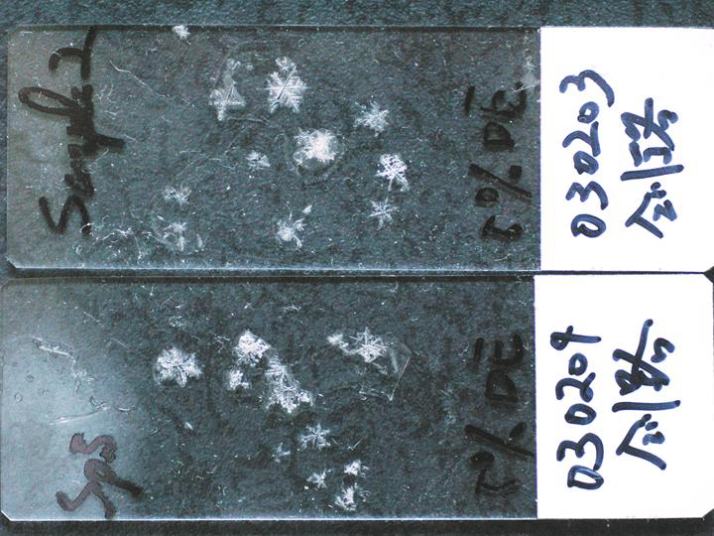

Replica liquids are easy to prepare, but some combinations of plastics and organic solvents can be used. Among them, the preparation method, in which acrylic is dissolved in methylene dichloride to make a 2-5% solution 2), seems to be the easiest because the materials are readily available. When attempting to make replicas more easily, transparent nail polish can be dripped over snow collected on a glass slide, or a spray of transparent oil-based paint can be sprayed onto a glass slide and the snow adheres to it. On this page, I would like to show you how to make a replica of snow crystals and various replicas.

How to make a replica of snow crystal

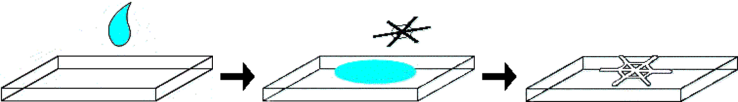

After dropping the replica liquid onto a slide glass, place the snow crystal on it, and let the solvent air-dry at a temperature below 0°C (about 6 hours).

The method with a light-curing resin

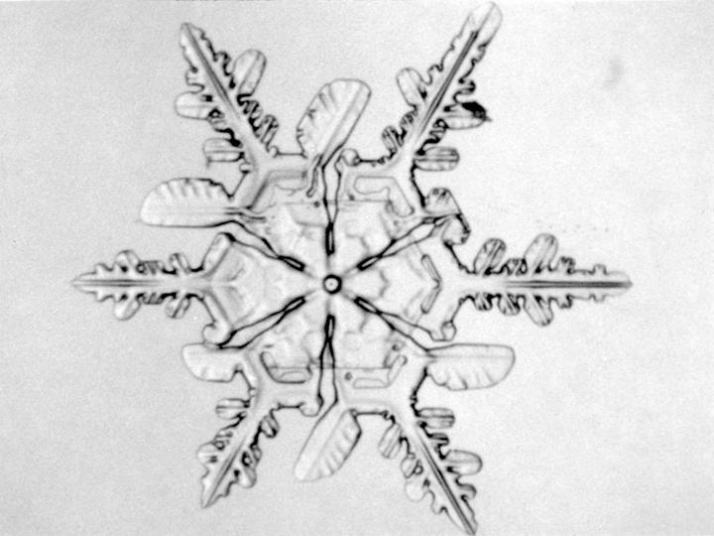

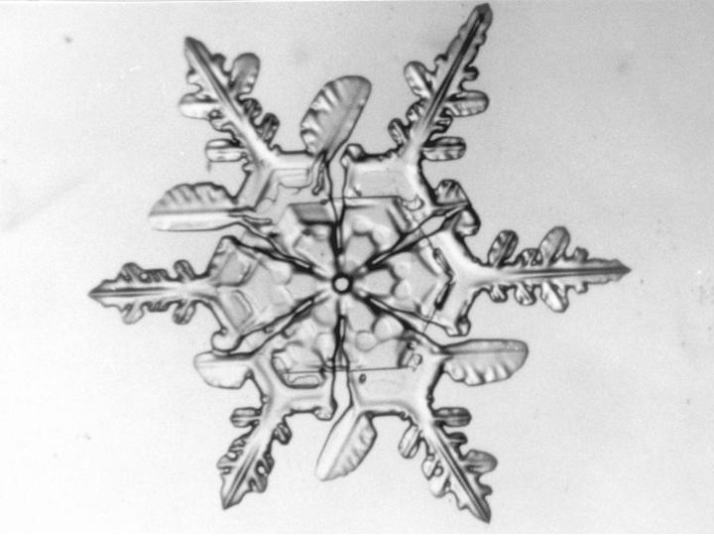

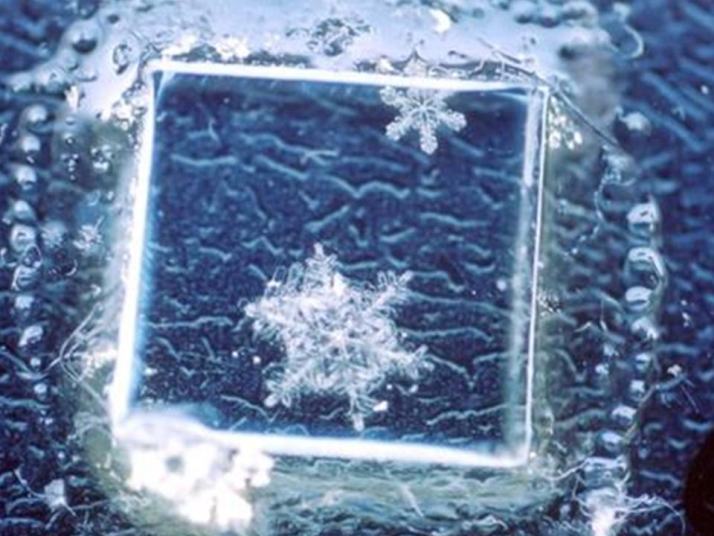

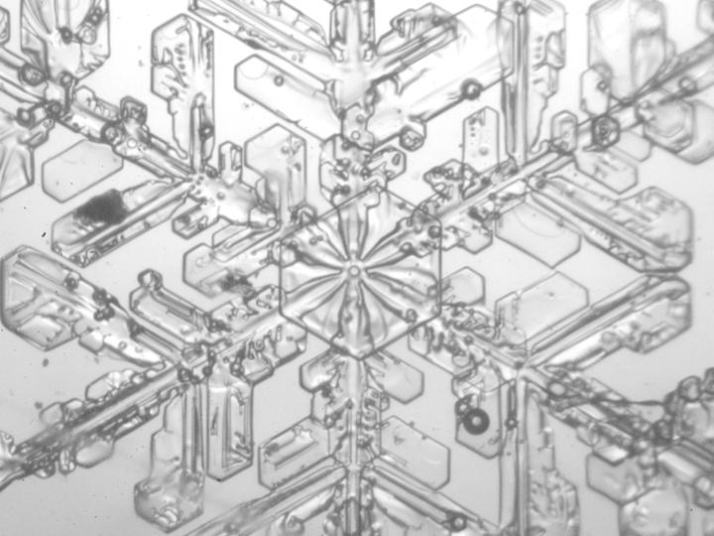

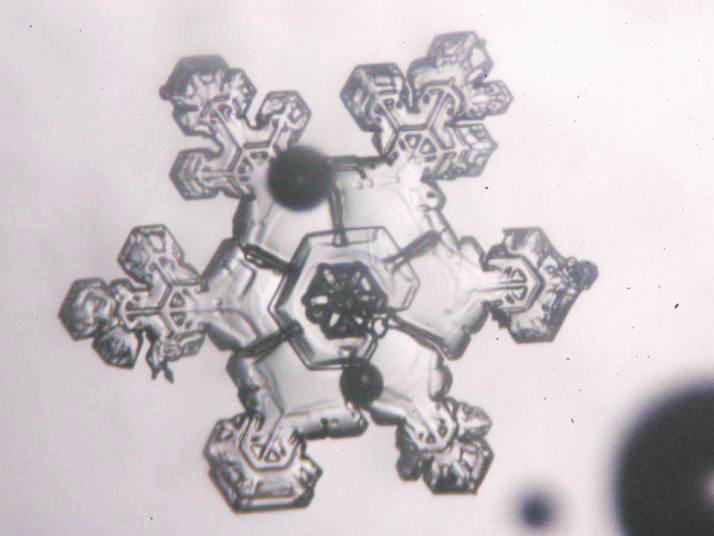

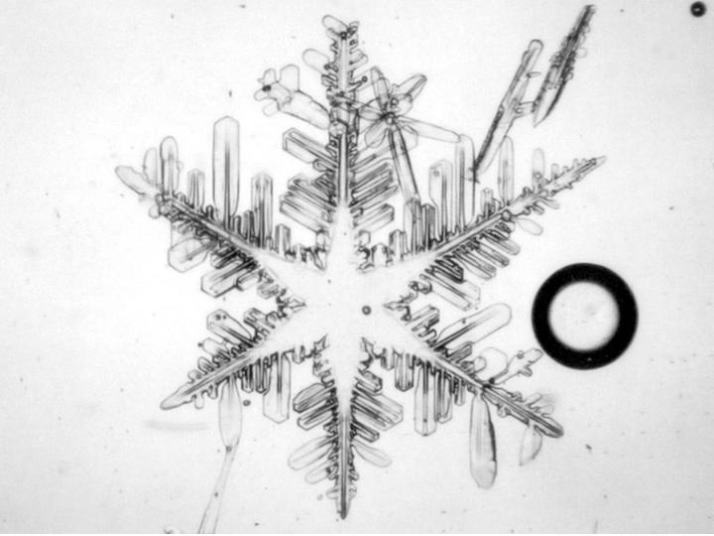

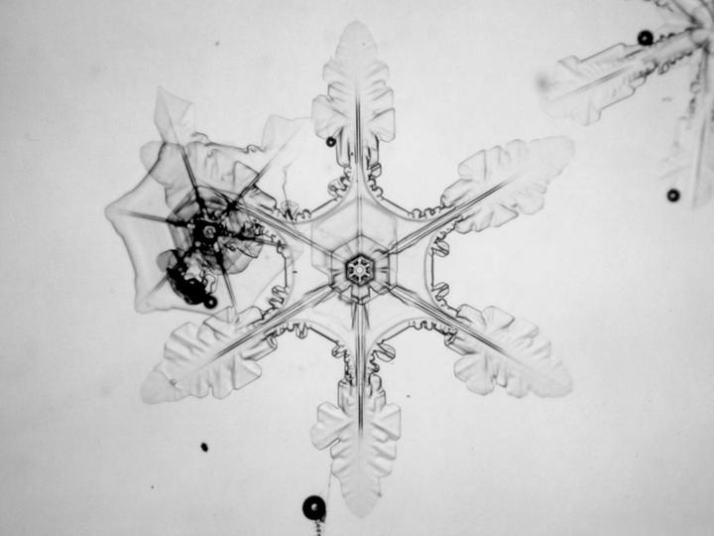

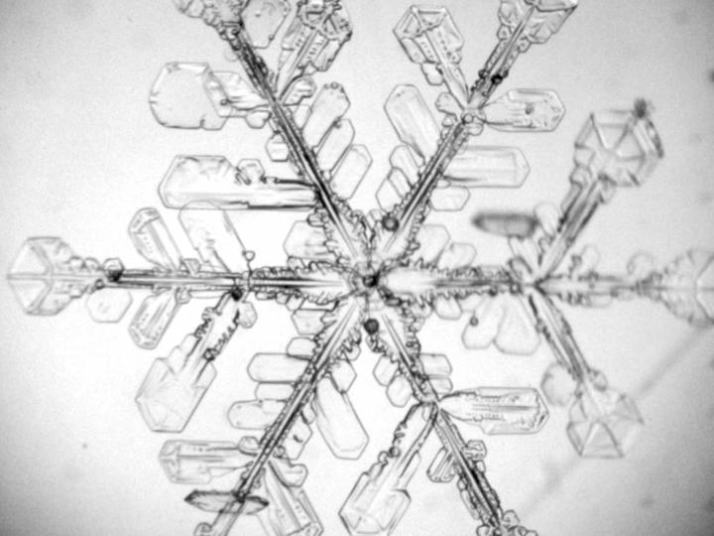

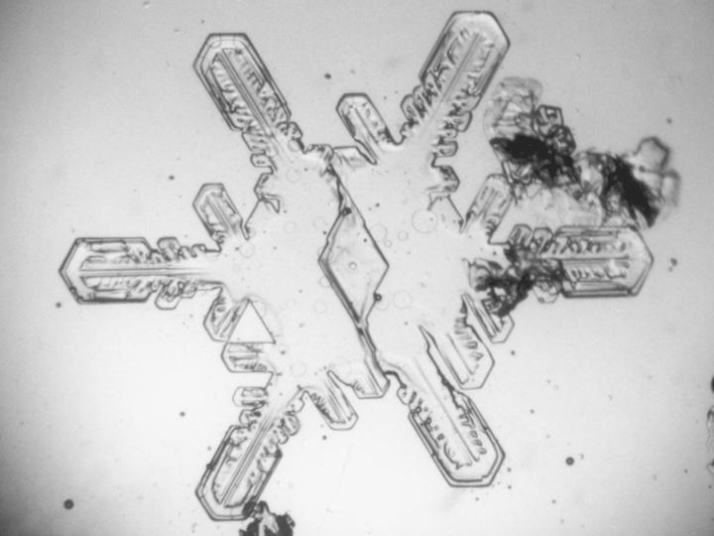

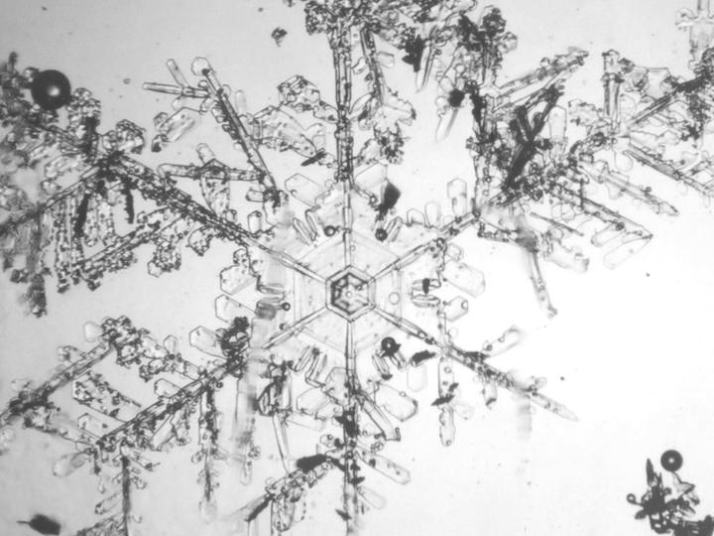

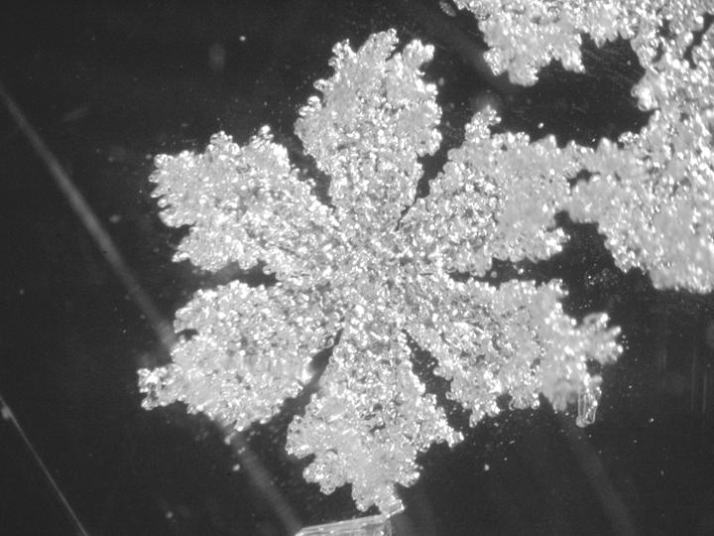

By using light-curing resin, it becomes possible to make the replica by embedding the whole crystal in transparent plastic 4), 5). It is confirmed experimentally that the replica saves the surface structure of snow crystals at the level of sub-micrometer 6). So, when I observe it with a microscope, I am able to see the figure of the snow crystal in detail as if it is floating in the view of the microscope.

In this method, I can store the 3D structure of snow crystals for a short time and surely. I think the prepared replicas are valuable as specimens of snow crystals that do not have a thing same for two.

The light-curing resins used in this method require some characteristics. The usable resins are limited, and many of them are not inexpensive.

However, this method can produce replicas of snow crystals that preserve the overall shape of the crystals in a short time and reliably. Although the cost of materials is a little higher, the pleasure of preserving the detailed shape of a snow crystal is very great.

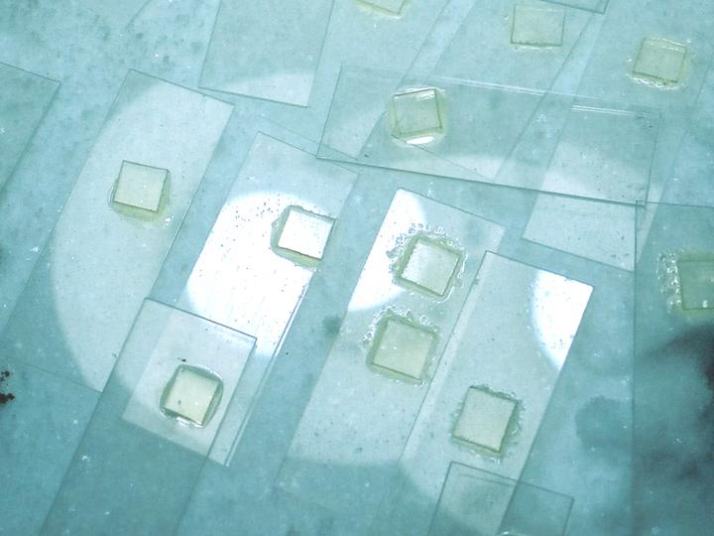

Light-curing resin is dripped onto the snow crystals, then a cover is placed over them. After the resin is cured, the water is allowed to evaporate.

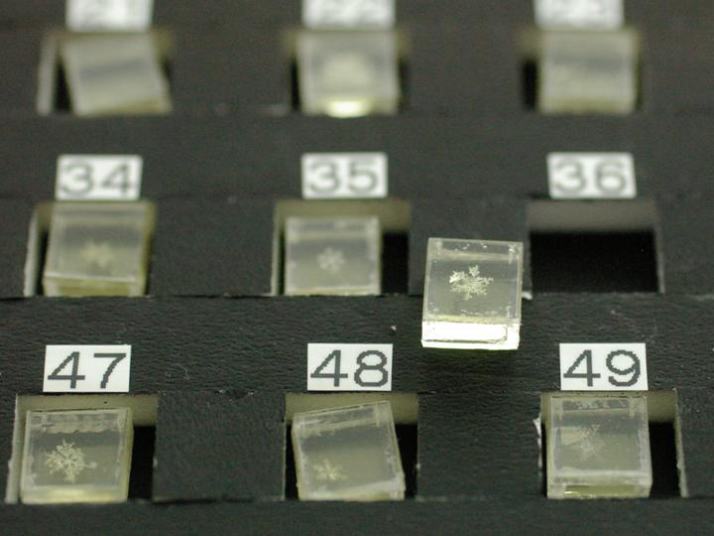

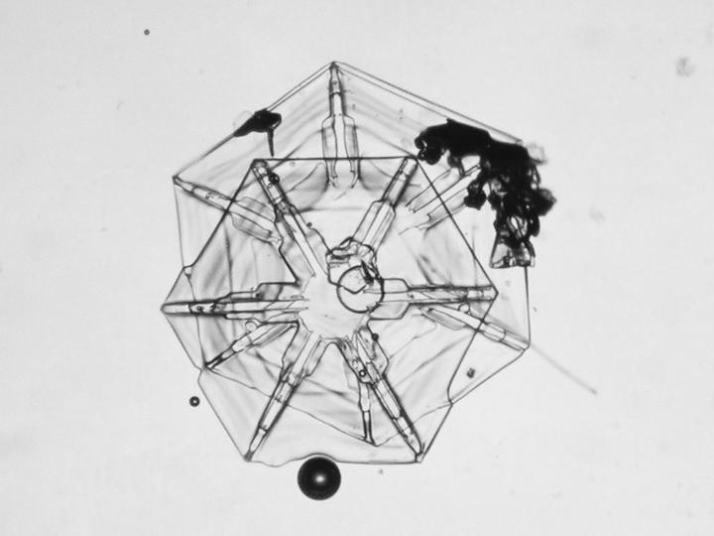

The replica embedded in a resin block

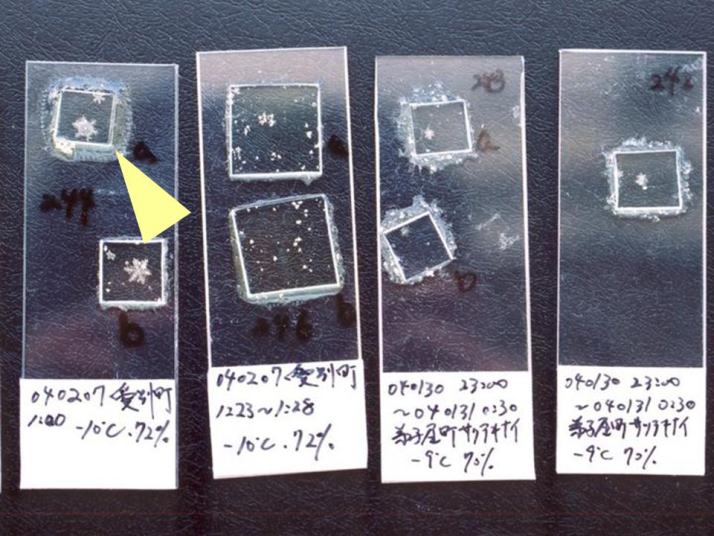

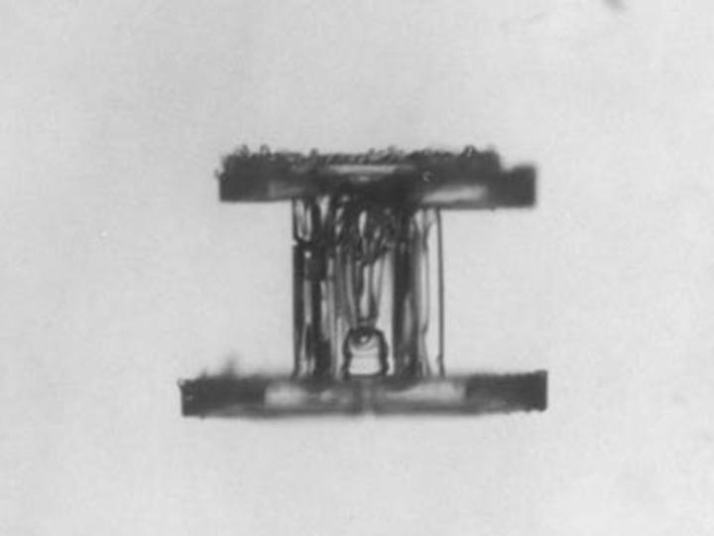

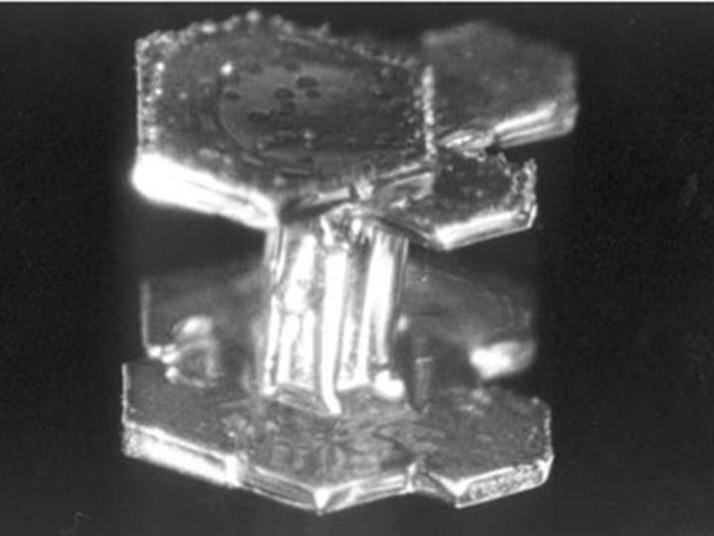

The replica embedded in a resin block is a further development of a replica fabrication method using light-curing resin 7). In this replica, snow crystals are encased in a resin layer several millimeters thick, so they can be observed with a microscope from all directions: top, bottom, left, right, front, and back.

In addition, although not shown on this page, when the surface structure of snow crystals is examined in detail, replicas are made by preserving a portion of the crystal and preparing its shape 8), 9), 10), 11). These replicas are also made using light-curing resin. Using such replicas, I am examining the 3D morphology and surface microstructure of snow crystals.

The replica of the snow crystal embedded in a resin block. The structure of snow crystals is preserved as internal voids in the resin.

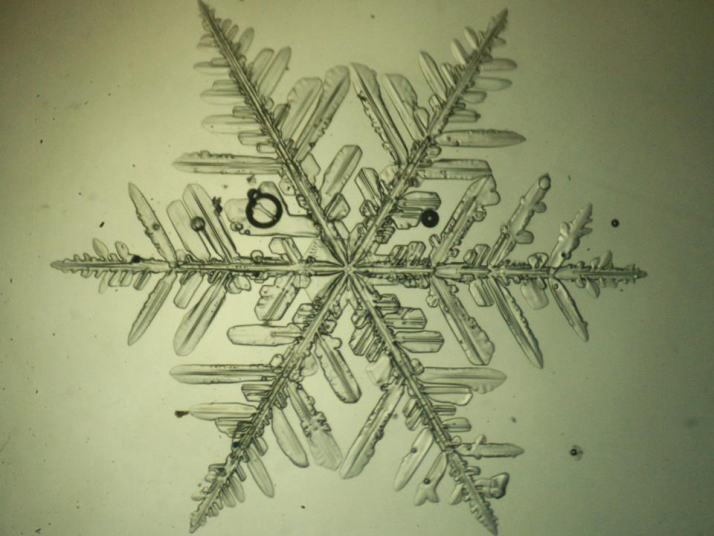

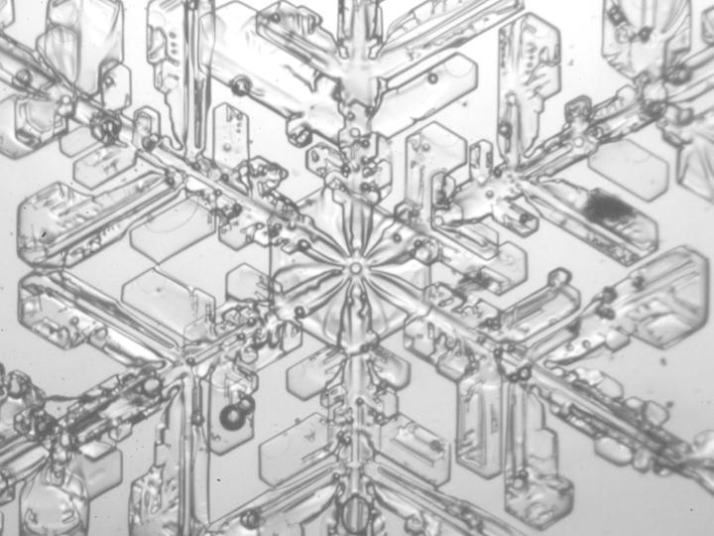

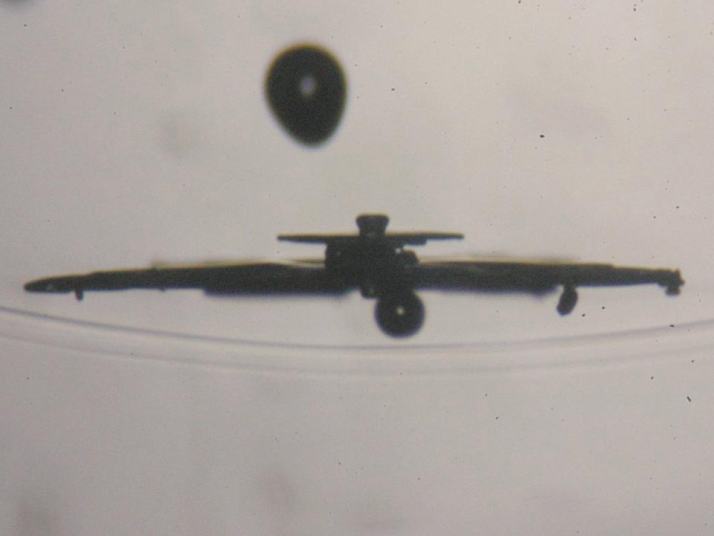

Images of a snow crystal captured from three directions using a replica embedded in a resin block. This snow crystal is a double plate type with protruding bases on the top and bottom of the center column, and I can see that the area near the center has a skeletal structure. I can also see that there is a small protrusion in the center of the crystal.

The 3D structures of snow crystals like this one are introduced in the gallery.

Various replicas (made with light-curing resin)

Refernces

1) Schaefer, V. J., 1941: A method for making snowflake replicas. Science, 93, 239-240.

(https://doi.org/10.1126/science.93.2410.239)

2) Takahashi, T. and N. Fukuta, 1988: Ice crystal replication with common plastic solutions. J. Atmos. Oceanic Technol., 5, 129-135.

(https://doi.org/10.1175/1520-0426(1988)005<0129:ICRWCP>2.0.CO;2)

3) 四手井鋼英,1951:雪のレプリカ.雪氷,13(1), 20-22.

(https://doi.org/10.5331/seppyo.13.20)

4) 柳 敏,2005:光硬化性樹脂を用いた雪の結晶プレパラートの作製.平成16年度東レ理科教育賞受賞作品集,27-30.

(https://www.toray-sf.or.jp/awards/education/pdf/h16_07.pdf)

5) Yanagi, S., 2005: Application of light-curing resin to the preparation of falling snow and frost. J. Phys. Educ. Soc. Japan., 53(1), 56-59 (in Japanese).

(https://doi.org/10.20653/pesj.53.1_56)

6) Yanagi, S., A. Kubo, T. Kameda, J. Tamaki, A.M.M. Sharif Ullah, 2015: Replication technique of snow crystal using light-curing resin and its copying accuracy. Seppyo, 77(1), 75-89

(in Japanese).

(https://doi.org/10.5331/seppyo.77.1_75)

7) Yanagi, S., 2009: Three-dimensional structure of snow crystals observed in snow crystal replica. Abstracts of the JSSI & JSSE joint conference 2009, Sapporo, The Japanese Society of

Snow and Ice, p144 (in Japanese).

(https://doi.org/10.14851/jcsir.2009.0.114.0)

8) Tamaki, J., S. Yanagi, Y. Aoki, A. kubo, T. Kameda and A. M. M. Sharif Ullah, 2012: 3D Reproduction of a snow crystal by stereolithography. J. Adv. Mech. Des. Syst. Manuf., 6(6), 923-935.

(https://doi.org/10.1299/jamdsm.6.923)

9) Yanagi, S., A. kubo, T. Kameda and J. Tamaki, 2012: Measurement of microstructure of snow crystal surface replicated to light-curing resin. Abstracts of the JSSI & JSSE joint conference

2012, Fukuyama, The Japanese Society of Snow and Ice, p13 (in Japanese).

(https://doi.org/10.14851/jcsir.2012.0_13)

10) Yanagi, S., A. kubo, T. Kameda and J. Tamaki, 2013: Comparison of front and back surfaces of snow crystals observed in snow crystal replica. Abstracts of the JSSI & JSSE joint

conference 2013, Kitami, The Japanese Society of Snow and Ice, p141 (in Japanese).

(https://doi.org/10.14851/jcsir.2013.0_141)

11) Yanagi, S. and T. Kameda, 2016: Layered structure of 4 to 27 μm thickness observed in a back surface of snow crystals. Abstracts of the JSSI & JSSE joint conference 2016,

Nagoya, The Japanese Society of Snow and Ice, p78 (in Japanese).

(https://doi.org/10.14851/jcsir.2016.0_78)